Key Features

- Ultra-High Accuracy: Detects flatness variations with resolution as fine as 0.1 micron.

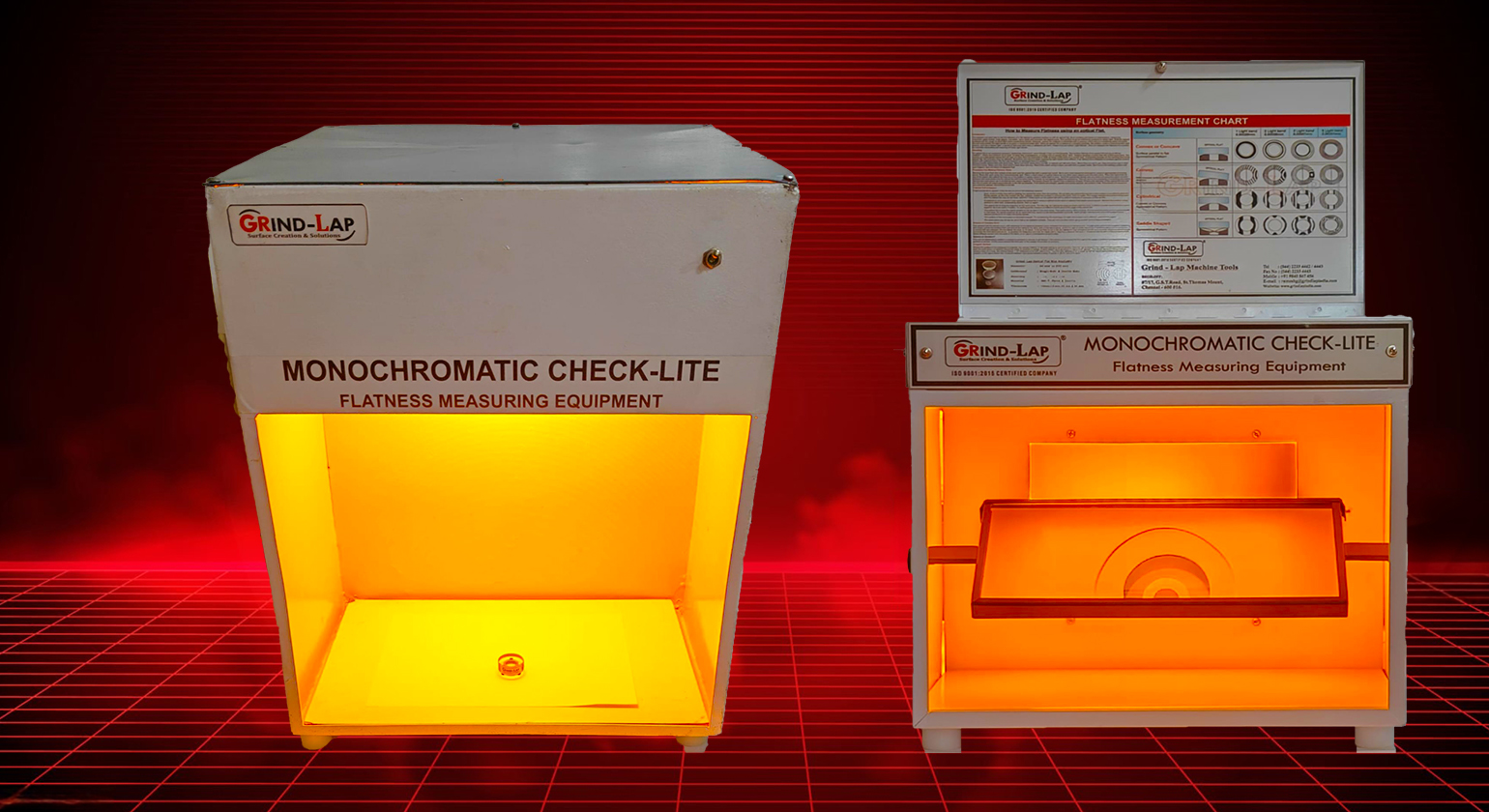

- Monochromatic Light Source: Uses sodium vapor light to produce clear and sharp interference fringes.

- Non-Destructive Testing: Ideal for sensitive, high-precision instruments without causing wear or damage.

- Compact & Portable Design: Suitable for laboratory and shop-floor conditions alike.

- Easy Interpretation: Interference fringes allow visual estimation of surface flatness in real-time.

- Versatile Use: Compatible with lapped surfaces such as granite surface plates, gauge blocks, and optical flats.